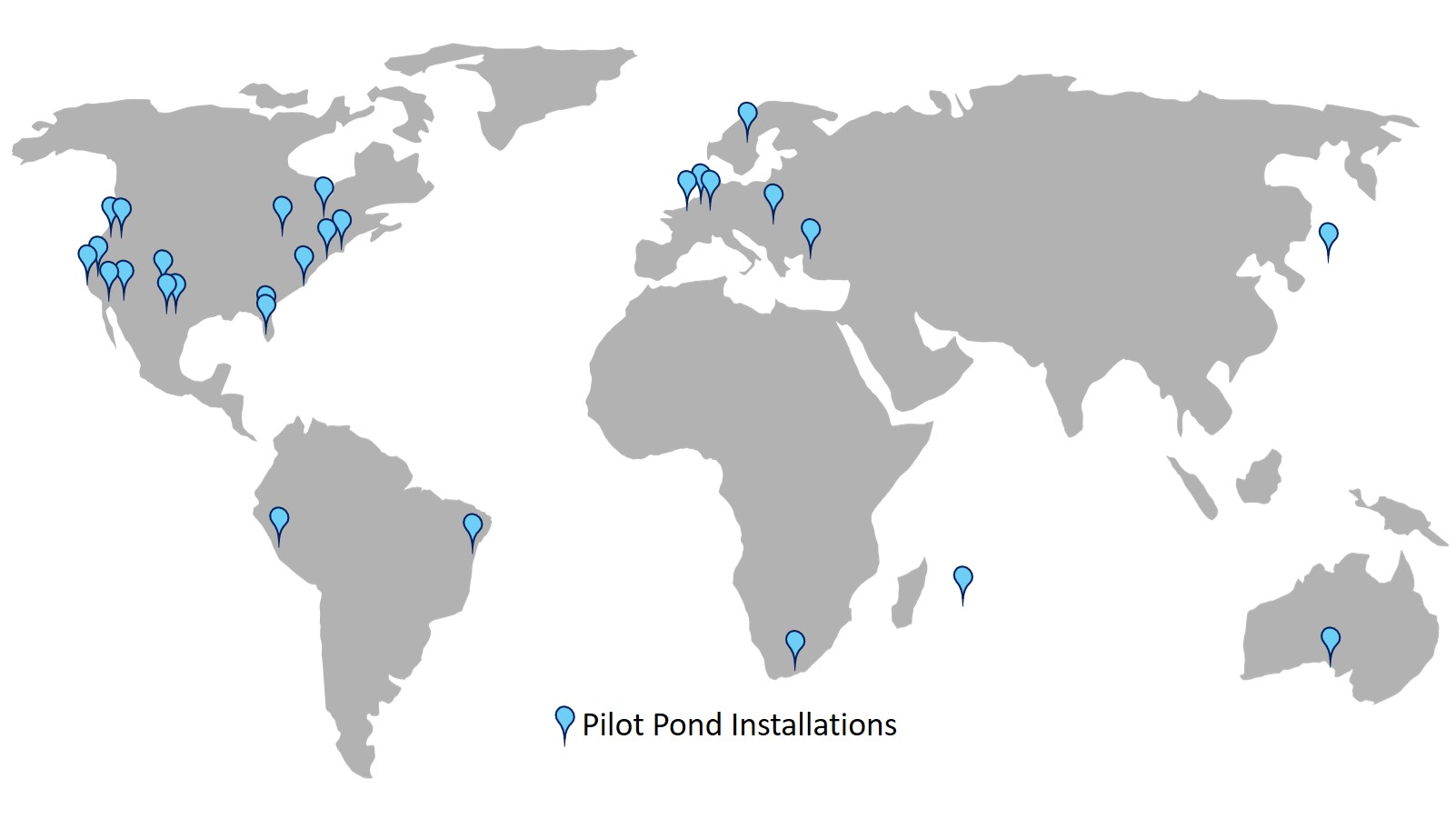

One of MicroBio Engineering’s core skills is creating new technology to support our research and project partners. MBE’s equipment has seen significant use in labs and field sites around the world, and new photobioreactor and monitoring systems are currently in development.

Mini Ponds

The RW0.5, RW0.5i, and RW3.4 were MBE’s original designs for small-scale microalgae cultivation. Today’s models are optimized for efficient mixing, easy cleaning, and straightforward setup. These reliable workhorses are a common sight at major research facilities. Look for the distinctive white rotomolded tank, stainless steel frame, and black plastic supports in the background of many microalgae publications.

MBE’s engineers approached benchtop microalgae research from two angles: simplicity and control. Their first photobioreactor, the bubble-column array (BCA-PBR), was built for cost efficiency, high-volume cultivation, and low barrier to entry. This system supports CO₂ and air mixing, light dimming, and temperature regulation across fourteen 1-liter glass columns. For a more precise cultivation approach, the automated algae cultivator (AAC-PBR) prioritizes advanced control at a smaller scale. Developed from the ground up, it features a custom Python-coded control system, real-time backscatter OD measurement, full seasonal climate simulation, temperature and pH monitoring, stepped-capacitance level sensing, mixing speed control, and automated nutrient media dosing, harvesting, and top-off.

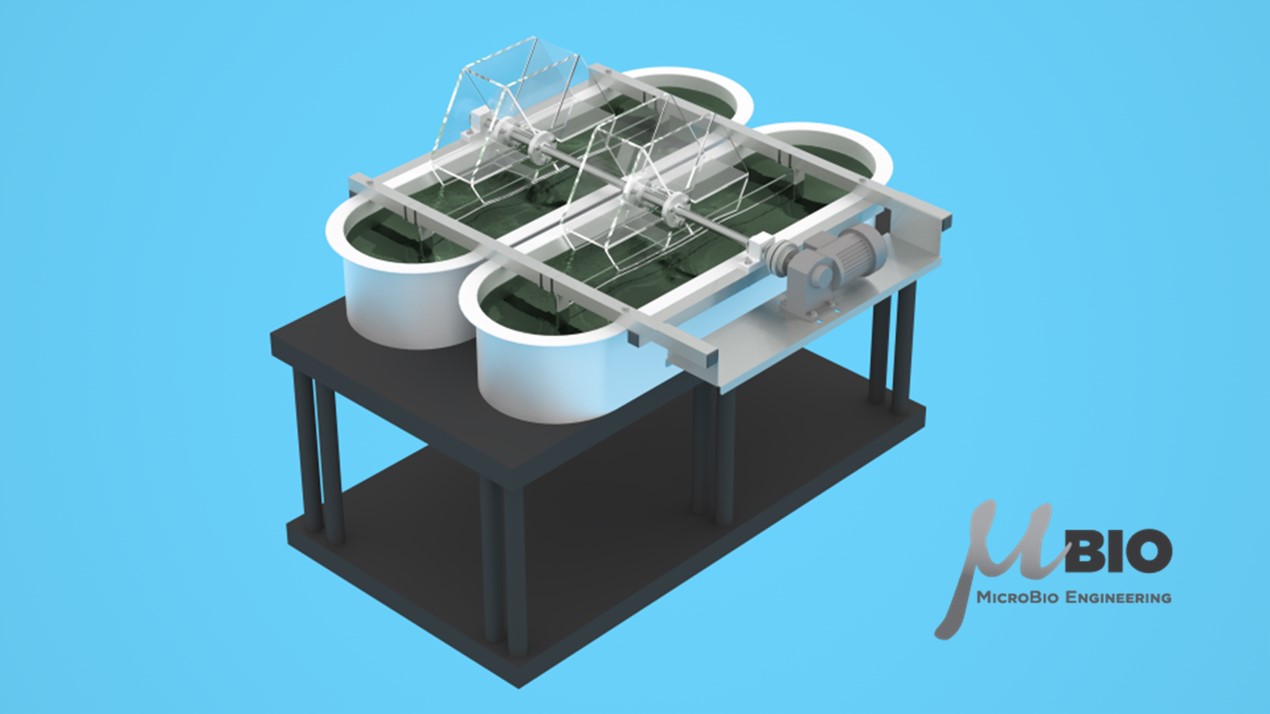

Originally nicknamed “A Pond in a Crate,” the RW22-101 (22-101m²) series were designed for rapid deployment and ease of transport. Developed in partnership with Andre Harvey and Colorado Linings, these systems feature a custom-welded, scrim-reinforced polyethylene liner, a stainless steel paddlewheel station, and a self-supporting wire-rope tensioning system. This design allows a transformation from crate to a fully assembled 5,000–25,250 L raceway pond in under a day. Despite their modular, prefabricated construction, these ponds are built to last—several RW43 units have been assembled, disassembled, shipped, and reassembled multiple times over nearly a decade of continuous use.

The RW200-600 (200-600m²) series were an answer to projects or microfarms requiring a larger cultivation area that could still be rapidly deployed. These sturdy ponds are pre-designed at several scales, requiring little infrastructure or site prep compared to concrete or earthen ponds of similar sizes. The integrated posts supporting the walls allowed a full-enclosed, ventilated hoop greenhouse option to control culture contamination. Assembly time is reduced by a tailored rugged liner, pre-bent corrugated walls, and a custom light-weight 4.5m FRP paddlewheel with pre-formed SS316 blades. Outside of those pieces, all other components can be sourced from local suppliers (lumber, fasteners, masonry, etc).

While developing the RW200-600 systems, MBE’s engineers set out to reinvent the paddlewheel for large-scale algae raceway mixing after identifying several weaknesses in the traditional approach. MBE’s solution: the LM-PW; a hexagonal hollow FRP shaft coated with food-grade UV-blocking epoxy, featuring detachable hubs supporting SS316 16-gauge custom-bent blades. Designed for practicality, the shaft is lightweight enough to be lifted and installed by hand, with all components secured using SS316 fasteners inside the pond for easy access. This durable yet energy-efficient design offers optimal open-raceway mixing and can be integrated seamlessly into existing ponds of any size.

Please contact us here for equipment inquiries.