Technoeconomic Analysis and Life Cycle Assessment

TEA/LCA

MicroBio Engineering’s deployment consulting services help transform pilot designs or conceptual plans into full-scale installations. For a more comprehensive understanding of your system, we recommend pairing this with technoeconomic analysis (TEA) and life cycle assessment (LCA). TEA evaluates the commercial potential of your project, while LCA assesses its environmental sustainability—together providing a well-rounded basis for strategic decision-making.

Technoeconomic Analysis

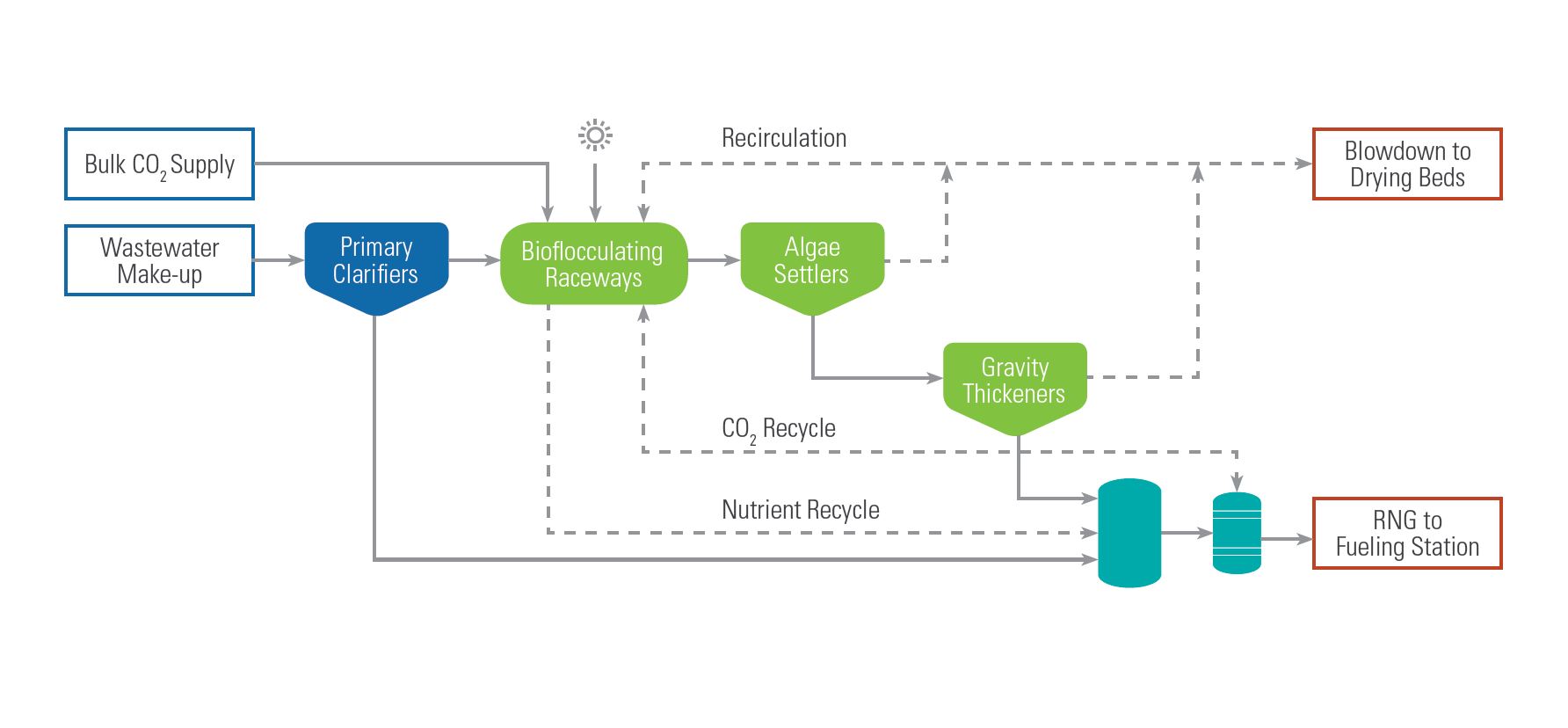

A technoeconomic analysis (TEA) helps businesses evaluate the financial feasibility of a project, both in the near term and over time. The process begins with a flow diagram outlining major equipment and product pathways, followed by a mass balance that quantifies inputs, outputs, waste, and co-products. Capital and operating costs are then calculated and annualized to compare against projected revenue streams. MicroBio Engineering can deliver a comprehensive TEA, including a detailed cash flow and rate of return report for investors, along with a supporting technical report. Our services include:

Process Flow Development

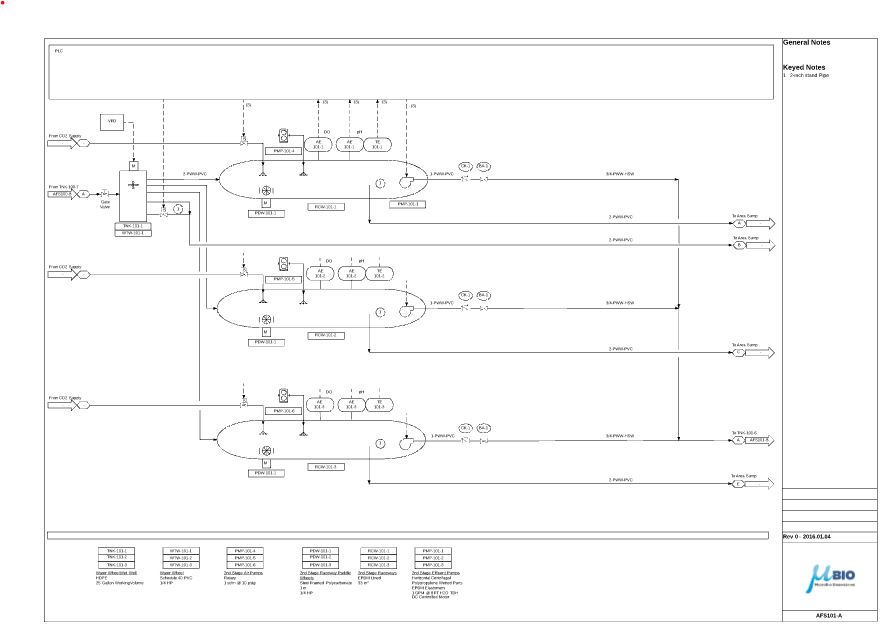

Process and Instrumentation Diagrams (P&IDs)

Mass and Energy Balances

Capital and Operation Cost Estimation

Cash Flow Analysis

Scenario Comparison

Interpretation of Results

Environmental Sustainability and Process Economics (ESPE) model

MicroBio Engineering’s Environmental Sustainability and Process Economics (ESPE) model allows our engineers to simplify this complex process, ensuring that our customers can make the right decisions when upgrading or starting a new product line.

Life Cycle Assessment

Life cycle assessment (LCA) is a tool used to assess the full environmental impact of a product’s life. This includes the impact due to raw materials production, materials processing, manufacturing, customer end use, and the final disposal of a given product. An LCA is required for approved pathways of the California Low Carbon Fuel Standard (LCFS) as well as the US EPA Renewable Fuel Standard (RFS). In addition, the energy and mass balances performed during an LCA are the starting point for process flow analysis, which provides vital information for process improvements energy and cost efficiency. MicroBio Engineering has extensive experience in the analysis of biofuels, algal animal feeds, and wastewater treatment. We offer full life cycle analysis of your product which includes:

Definition of System Boundaries and Functional Units

Life Cycle Inventory

Energy Balance

Mass Balance

Impact Assessment

Interpretation of Results

Integration with openLCA and Ecoinvent

MicroBio Engineering uses our proprietary Environmental Sustainability and Process Economics (ESPE) model to assess biofuel and wastewater treatment processes in addition to openLCA software with the ecoinvent life cycle inventory database. Our engineers are experienced with the National Energy Technology Laboratory (NETL) CO₂ Utilization (CO2U) Guidance Toolkit and will produce LCAs meeting USA Department of Energy Funding Opportunity Announcements requirements.